-

abbu riyaz

- 28 Oct 2017

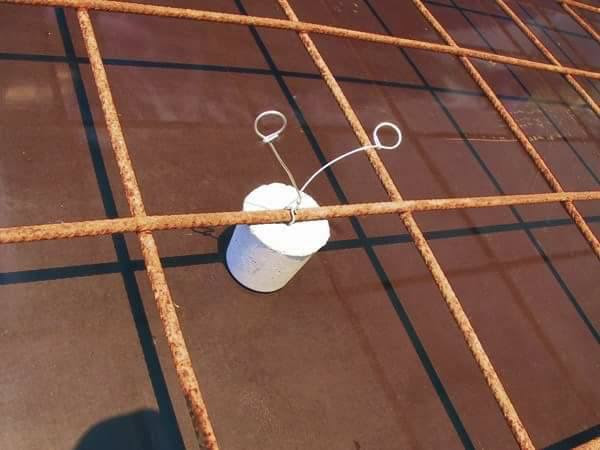

Reinforcement Cover

Reinforcement Cover Reinforcement Cover is essential to the steel reinforcement bars. Bars are surrounding sufficient impermeable concrete to protect from corrosion.…

-

abbu riyaz

- 27 Oct 2017

Plastic formworks for concrete construction

Plastic formworks for construction is to keep fresh concrete in position to gain strength. With the help of formworks, concrete is…

-

abbu riyaz

- 26 Oct 2017

RCC Columns Pedestals and Footings

RCC Columns Pedestals and Footings is to give good strength and durability to structural members. Improper concrete leads to corrosion of…

-

abbu riyaz

- 23 Oct 2017

Roof Repairs

The Roof repairs and repairing methods explains in these post. There are various methods follows for rectification of old roof…

-

abbu riyaz

- 15 Oct 2017

Repairing Concrete Column Cracks and Damages

Repairing concrete column cracks and damages is essential. The column concrete damages are becoming critical in mass structures like shopping malls,…

-

abbu riyaz

- 12 Oct 2017

Corrosion protection

Corrosion protection of underwater pile is essential in aqua construction. Eliminating this corrosion problem is very hard, the corrosion is…

-

abbu riyaz

- 11 Oct 2017

Methods of Ground Water Control in Excavations

The Methods of Ground Water Control in Excavations explains in this post. These techniques use to prevent groundwater entering into…

-

abbu riyaz

- 09 Oct 2017

Structural strengthening

Structural strengthening of concrete structures considers when the existing structure damages. And alteration of the structure is to make due…

-

abbu riyaz

- 08 Oct 2017

Grouting techniques

Grouting techniques use to prevent water leakage in massive and other water retaining systems. Underground structures like tunnels, hydroelectric power plants, storage…