Concrete in construction Field is a mixture of paste and aggregates. It composes of fly ash, fine and coarse aggregate, water and chemicals. The fine aggregates are sand and coarse aggregates are gravel. By hydration, the paste hardens and gains strength to form the concrete.

Concrete in construction Field

Concrete is soft in newly mix, strong at hardens. Hence concrete uses to build bridges, superhighways, houses, and dams.

There are some important factors involve in the manufacturing process of concrete. They are

- Proportioning

- water-cement ratio

- Ingredients

- Hydration

- Placement

- Curing and

- Special techniques

1. Proportioning

Proportioning and mixing are the main things in making a strong concrete. so choose the materials carefully. The mixture that does not have enough paste to fill the gaps between the aggregates is difficult to place. And produce rough surfaces. A mixture of a high cement paste is easy to place. And produce a smooth surface.

2. water-cement ratio

The quality of the paste determines the character of the concrete. The strength of the paste depends on the ratio of water to cement. It is the weight of the mixing water divided by the weight of the cement. High-quality concrete produces by lowering the water-cement ratio without losing the workability of fresh concrete. And allowing it to properly place and cure.

A properly design mixture possesses desire workability for the fresh concrete and the long-life and strength of the concrete.

3. Ingredients

Natural water drinkable and has no bad taste or smell used as mixing water for concrete. Impurities in mixing water affect setting time and strength. It causes efflorescence, staining, corrosion of reinforcement, and reduce lifetime. Drinking water suitable for mixing concrete and aggregates are to choose properly.

The aggregates to be clean and free from matter that affects the quality of the concrete.

4. Hydration

Aggregates, water, and the cement combine, the mixture hardens. By hydration, the paste hardens and get the strength to form concrete. During this reaction, a node forms on the surface of each cement particle. The node grows and expands until it links up with nodes from other cement particles.

5. Placement

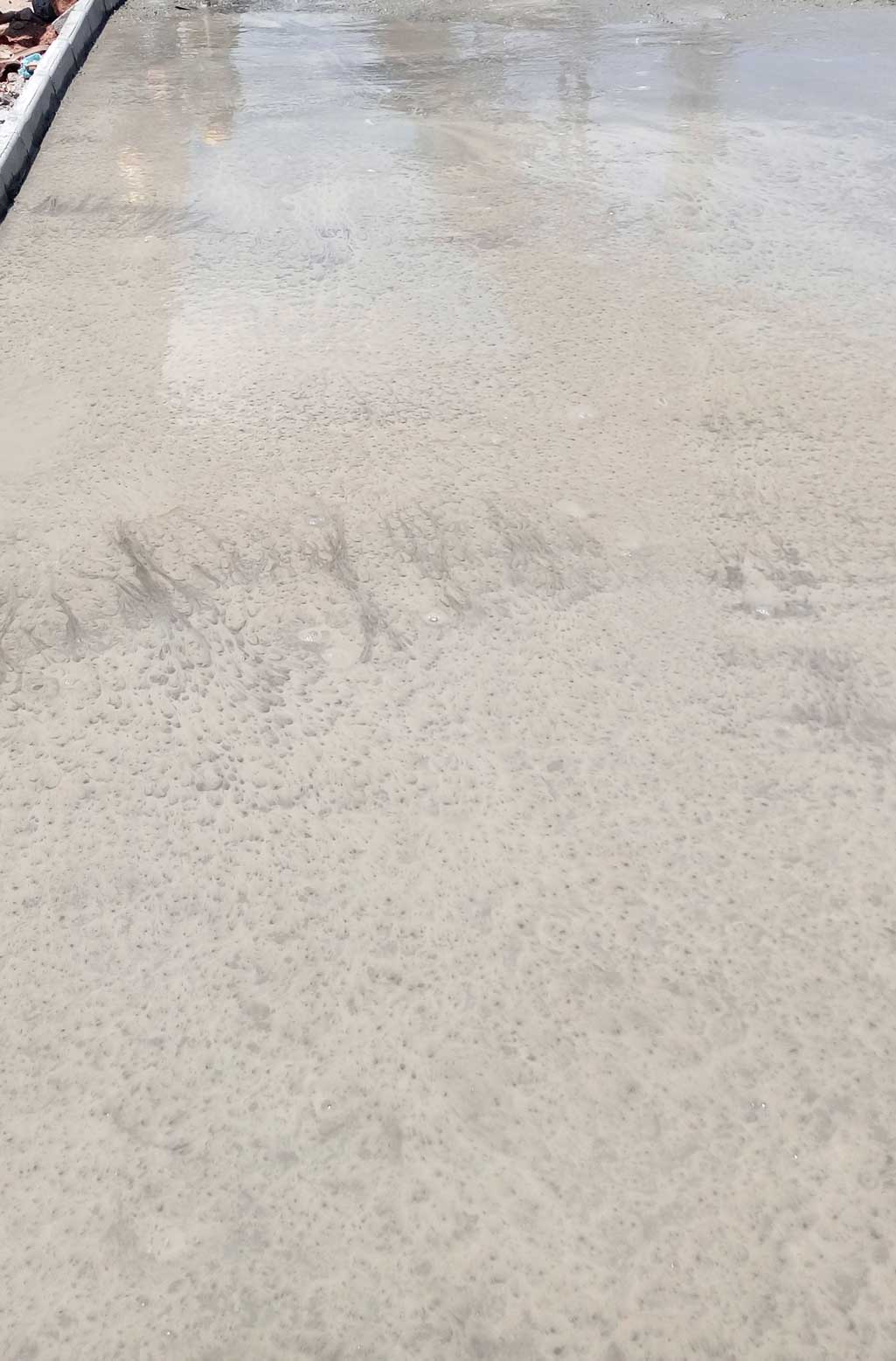

The concrete thoroughly mixes and workable is places in forms before the mixture becomes too stiff. At placement, the concrete compact within the forms to reduce honeycombs.

For slabs, concrete makes ideal to stand until the surface moisture film disappears. A wood or metal hand float uses to smooth off the concrete. Floating produces an even, but slightly rough, texture that has good slip resistance. And use as a final finish for exterior slabs. If smooth, hard, dense surface requires, floating follows by steel trowels.

6. Curing

The curing begins after the exposed surfaces of the concrete have hardened sufficiently to resist damage. Curing ensures the continued hydration of the cement. So that the concrete continues to gain strength. Concrete surfaces cure by sprinkling with water fog. Other curing methods prevent evaporation of the water by sealing the surface with special sprays called curing compounds.

7. Special techniques

It uses for curing concrete during cold or hot weather to protect the concrete. The longer the concrete is wet, the stronger it becomes. The rate of hardening depends upon the composition, fineness of the cement, mix proportions, moisture, and temperature. Concrete continues to get stronger as it gets older. Most of the hydration and strength gain take place within the first month of concrete’s life cycle.

Leave a Reply