There are different Plastic Formwork types use in the construction of structures.

Plastic formworks for concrete construction is to hold freshly place concrete in a correct position. And to gain strength. With the help of formworks, concrete easily makes into various shapes and size.

There is different material uses to make formworks. Mainly timber and steel. Plastic gives a number of advantage, compares to other materials, like durability, cost-effectiveness, and flexibility.

Plastic Formwork Types

There are Different Plastic Formwork types.

Siscon

It is a type of plastic forms uses to construct various structural elements. Like walls, columns, and slabs.

Formworks for Walls

It is for the construction of boundary walls, retaining walls, shear walls. And for rainwater drains, storm drains and irrigation canals.

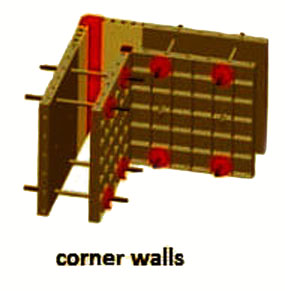

1. Corner wall formwork

It uses in the construction of corner walls. It makes with simple joints. And fewer supports.

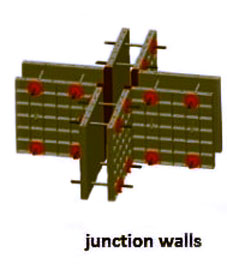

2. Junction wall Plastic formwork

It uses in the construction of junction walls. It is easy to handle.

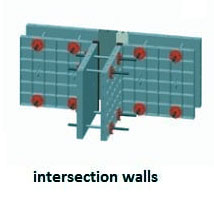

3. Intersection wall plastic formwork

It uses in the construction of intersection walls. And easy to fix and remove.

Plastic Formworks for Column

Plastic Formworks for Column

It manufactures from specific grade plastic. Other materials do not stick to it. And no chemical reactions occur between concrete and the plastic form. And no patch forms on the surface of the concrete.

1. Nova Plastic Formwork System

It produces from the composite plastic material. And use in salt and fresh water.

2. Moladi Formwork

It is lightweight and reusable. It makes to handle bad qualities. And problems relates to formworks.

Objectives of Formworks

It needs attention to avoid damages. The formwork design and construction are controls by three principles:

1. Safety

It depends on the strength of formwork. Life of labors and public might be in danger if the formwork does not has strength.

2. Quality

Concrete shape accuracy. And the quality of a final surface of the concrete.

3. Economy

It is highly economical.

Advantages of Formworks

- Water resistant

- Recyclable

- Cost-effective

- Labor and

- Eco-friendly

- Low maintenance

Leave a Reply