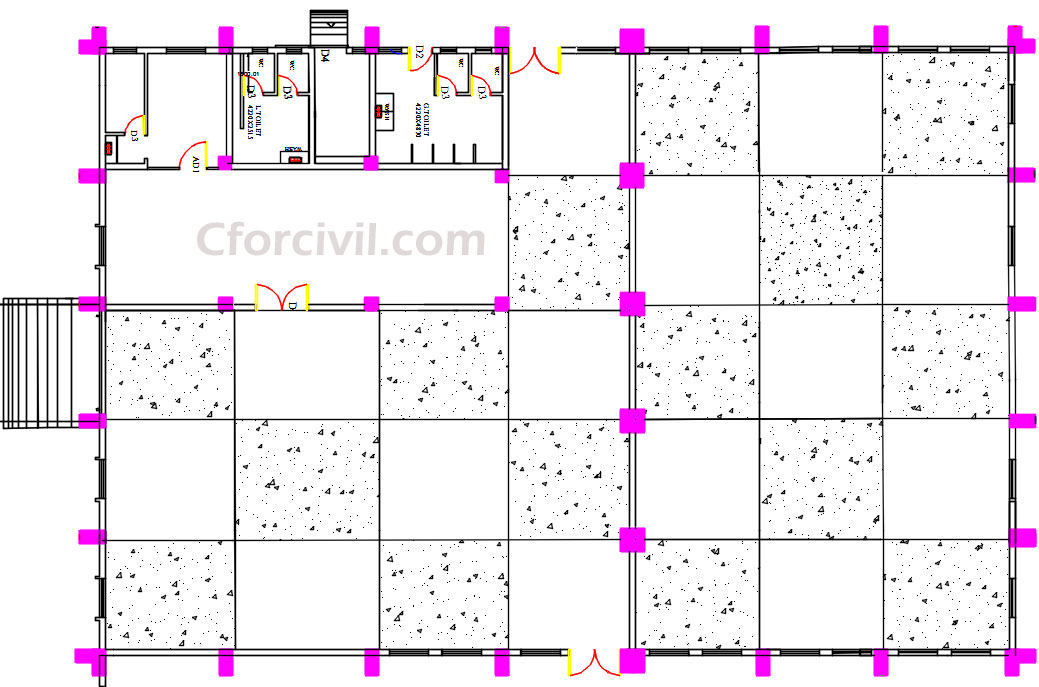

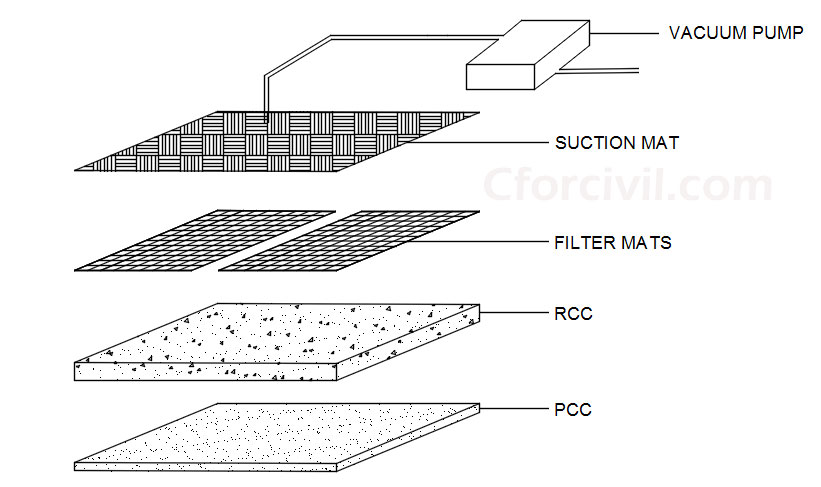

Vacuum Dewatering Flooring

Vacuum Dewatering Flooring discuss in this post. This is a process of removing excess water…

Concrete Sleepers

Concrete Sleepers introduces in the modern construction of railway tracks. Mainly sleepers are of concrete, timbers,…

Metal Sleepers Advantages and Disadvantages

The Metal Sleepers Advantages and Disadvantages are discussed in this post. Railway Track Sleepers are members which…

Types of Metal Sleepers

There are many Types of Metal Sleepers using in the construction of railway rail tracks. As it…

Metal Sleepers

Metal sleepers use widely in the modern construction of railway tracks. The Metal sleepers are of…