Scaffolding

Scaffolding is a temporary structure uses in building operations to support platforms for workmen. And…

RCC Column Construction Methods

RCC Column Construction Methods consist of various steps and procedures to follow in the construction…

Steel corrosion control methods

Steel Corrosion control methods are essential to prevent damage and the failure of structures. 40%…

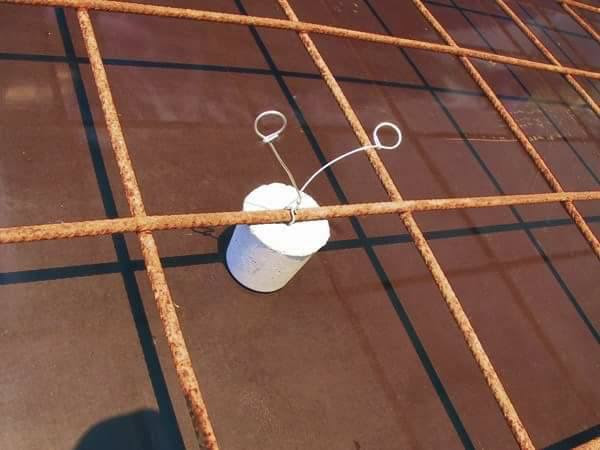

Reinforcement Cover

Reinforcement Cover Reinforcement Cover is essential to the steel reinforcement bars. Bars are surrounding sufficient impermeable…

RCC Columns Pedestals and Footings

RCC Columns Pedestals and Footings is to give good strength and durability to structural members. Improper…

Roof Repairs

The Roof repairs and repairing methods explains in these post. There are various methods follows…